Sandblasting / Glass bead blasting / Microblasting

Sandblasting

Sandblasting is the classic cleaning technique for fettling, de-scaling, roughing and matting, especially for steel and cast iron components. Sandblasting is frequently used before a coating is applied. G.W.P. possesses up-to-date blasting cabins, rotary tables and rotary baskets for small parts for gentle sandblasting.

Glass bead blasting

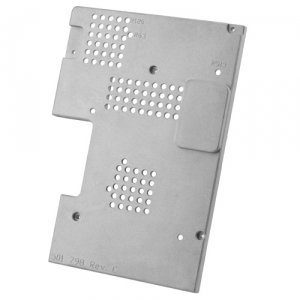

High-quality light metal components can be gently cleaned, deburred, smoothed or matted by means of glass bead blasting. This blasting technique is used both to prepare for coatings and to improve the structure of the surface finish. Glass bead blasting produces surfaces on aluminum components with a brighter and very attractive appearance. The surfaces are compressed when they are blasted; dimensional tolerances, edges and sealing surfaces are retained. G.W.P. uses modern injector rotary and pressure blasting systems for glass bead blasting.

Microblasting

Microblasting allows the very fine blasting of angled components and is used to produce structural changes, surface effects or prepare an adhesive base. Microblasting is a new pressure blasting procedure that can achieve highly precise results when the material and surface geometry are subject to special requirements. We use different blasting abrasives as needed (corundum, steel shot, spheres).