Aluminum sand casting for prototypes

Do you need aluminum prototypes and place a high value on freedom in construction and low tool costs?

Aluminum sand casting is particularly suitable for individual cast parts and aluminum prototypes up to a maximum of 100 units when an economical type of casting is required that can accommodate changes to the mold. Since the molds in aluminum sand casting are made of molding sand held together by clay or artificial raisin, the mold and mold core are relatively economic to produce but can only be used once.

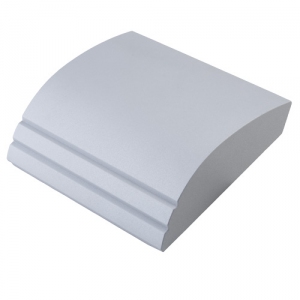

Characteristics of aluminum sand casting

Aluminum sand casting is distinguished by precise dimensions and an attractive service quality. Complex component geometries with undercuts are easily reproduced since the mold is only used once. The pressure tightness and tolerances are restricted in comparison to gravity die casting or die casting. Wall thicknesses must be greater than 2 mm when constructing components using the aluminum sand casting method.

Advantages of aluminum sand casting:

- Economic aluminum prototypes from 1 to 100 units

- High degree of freedom in construction

- The molds are easily and quickly changeable

- Molded parts weighing 100 - 3,000 g

- Possible construction area: 650 x 490 mm

- Including finishing and surface processing